Everything Else

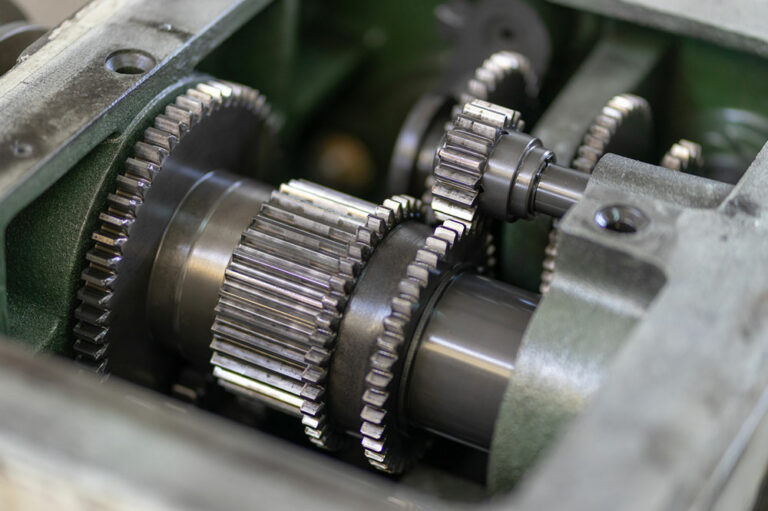

4 tips for industrial machine maintenance

For industry operations to function smoothly, it is paramount that the machinery is functioning well. It decides the efficiency, safety, and productivity of the industry. Machines also decide the manufacturing, processing, and production of the business. However, the machines’ performance depends on the kind of maintenance and care they receive. Regular maintenance improves the lifespan of industrial machinery and ensures that it delivers consistent performance. Here are a few tips for the proper maintenance of industrial machinery: 1. Clean the machinery regularly Cleaning industrial machinery can go beyond the basic dirt and debris. Cleaners need to pay special attention to areas that face an accumulation of contaminants in air vents, fluid reservoirs, and cooling fins. It is also important to use cleaners that are compatible with the machines. The cleaning process needs to be determined with importance to avoid abrasive cleaners and keep the surfaces from irreparable damage. Regular deep cleaning processes can come in handy to keep stubborn deposits at bay. 2. Lubricate it often The cleaning of industrial machinery goes beyond removing dirt and debris. One must pay special attention to areas with accumulated contaminants in air vents, fluid reservoirs, and cooling fins. It is also important to use cleaners that are compatible with the machines.